Prusa Core One Detailed Review

You may have come across my Youtube Video, which I published in September of 2025. If not, please check it out!

I wanted to go into a bit more detail on my review, as some content is just too much to cover for video format. While much of this is mentioned in the video, there is also a bit more information here. Like a more in-depth review? If so, keep reading!

Context / Background

To be honest, I wasn’t really looking to build a Prusa Core One. Back in April of 2025, John (3dprintingworld) and I decided to drive up to Rapid/TCT in Detroit, MI and he asked me if I’d like to build his Prusa Core One for content. I thought about it a bit and decided to take him up on his offer a few months later after his printer shipped. Side note: we live pretty close (in the same metro) and met at MRRF pre-Covid. I’ve known John for a while, and have been a big fan of his open source design printers (like the Mulbot, Mulcore, and Muldex). He is an amazing designer and it’s hard to keep up with all the cool stuff he is making. These days, he’s known for his print-in-place retractable light sabers. Go check out his web site if you’d like to learn more! You very well may have already printed one of his models- which can be found on Thangs, Printables, etc.

If you’ve been watching my channel for a while, I am primarily focused on Voron, VzBot and other Open Source DIY printers. I have always enjoyed the building and tweaking process. I also enjoy the troubleshooting process- when something doesn’t quite work right, digging in deep to understand why, and then fix it. The biggest reward is when it all comes together and the first layer of filament goes down.

Fortunately, a Prusa build isn’t that far off from an Open Source printer like a Voron. You will be taking a box of parts and making something really cool with it. There are a lot of other pluses- it has quite a bit more documentation and support available, leaving very little to research necessary. Another huge benefit is that there are profiles already available, and you don’t need to spend days or weeks doing printer calibration. At this point, I’ve already printed 10+ jobs and only used the stock profiles. The results have been very good, overall. They are comparable to what comes off any other well-tuned printer, whether a Voron, VzBot, or a Bambu. I am sure I could tune things a bit more but I’m happy with it..

So, let’s get into the build a bit:

Issues I ran into during the building process.

-

- I made a few mistakes along the way but nothing significant. The three biggest mistakes that I made:

- I reversed the base profiles. I didn’t realize this until 20 steps later.

- It took me about 15 minutes to fix.

- I was confused, so I went to ask Prusa why there was no “hole” for the self-tapping screw. While I was asking the question, I had a pretty good idea of what I did, and they confirmed it (mixed up a few profiles).

- Later on, I also mixed up a few of the parts that connected to the rods. This was also very easy to fix.

- At the end of the build, I ran into problems with the machine calibrating the belts. My Gantry must have been out of square, and/or my belts not completely tight. The calibration routine eventually caused the belt to fall out on the bottom right. This required me to tear down the toolhead, which was not a huge effort, but was a bit tedious.

- The RUBBER FEET. They do not have good adhesive. VHB is an easy fix, but Prusa.. come on! This was the biggest disappointment.

- I made a few mistakes along the way but nothing significant. The three biggest mistakes that I made:

- Initial Observations

- The build is very straight forward, documentation is a 9/10. There were a few spots where I’d prefer to see a bigger picture in addition to a zoomed in view, especially on parts like the base and Gantry.

- While the build is pretty easy, it is a bit daunting. For first time builders, it may take several weekends and evenings to build this successfully.

- The machine is quite heavy. So much metal. That is a good thing for stability, but a bad thing for portability.

- There are a lot of software features, which I’m not sure how I feel about yet. For example, I noticed the firmware does a heat soak on the bed, which probably isn’t a bad thing but does add to the startup time.

- Things I like about the printer

- The look and feel is very sleek and professional/

- The LCD screen has just about everything you can think of in terms of controls.

- The LED lighting is a nice quality of life feature, and it’s built right in. A white light for visibility, and an RGB light for status.

- Filament loading and unloading seem to work very well. You can do it all from outside the printer.

- Print quality out of the box was pretty good (as mentioned earlier). Some additional tuning / slicer tweaks could yield better quality. For my very first print, I chose the keychain. It had some small gaps in the letters.

- The sides are great- store filament on the right hand side, and use the left hand side for mods (like a tool holder).

- Removing the panels are pretty easy, because of the nylon fasteners. Those are a pretty cool way of keeping things together for assembly.

- The machine is pretty quiet! It can get a little noisy on travels, but overall it isn’t very loud. With the printer on the opposite side of the room, I could be on a Zoom call and not have to worry about it being heard.

- Prusa provides a lot of filament profiles with Prusa Slicer, for example, I found one for Sainsmart TPU and Prusament. Some of the other filaments I tried, like Polymaker, did not have profiles but I used the “Generic” for.These didn’t work as well out of the box and required some tweaking.

- Criticisms

- I have built over 10 Core XY machines, mostly open source (multiple of each: Voron, Hypercube Evolution, VzBot). The Prusa was more difficult to properly square the gantry with proper belt tension compared to the others. Despite having no “play” in the gantry, I still had problems with the repetitive “kamikaze” belt tension calibration that happens in the front right corner. I eventually had to use the “wrench hack” to square my gantry. After I did that, I re-tensioned belts and haven’t had a problem since.

- There are too many different fastener types. Simplifying the BOM would be great.

- I am not a fan of the constant gantry calibration that is ran by the firmware. it occurs during unloading and loading filament, and appears to be built into the homing process of the printer. I don’t understand how or why the gantry could get out of square so frequently that it needs to be calibrated for each print, which is annoying and also may cause belts to lose tension. It would be great if this feature could be turned off or selectively ran.

- The belt tensioning app isn’t very good. I used Pano Tuner instead, which easily detected the belt frequencies.

- I don’t like that the love board is mounted to the plastic part by only one screw. It can come loose too easily.

- Similarly, why not put an accelerometer in the love board, or include a nozzle board that can easily connect to it? Prusa offers an add-on, but it requires a lot of messing around with usb cables and routing wires.

- I would much rather use heat inserts than square nuts, though I understand why Prusa uses them.

- Some of the printed parts were not the best quality and had bridging issues, which made inserting square nuts more difficult than it needed to be.

- Inserting the filament into the Bowden tube is a little challenging. Sometimes I need to trim the end of the filament to allow it to go in. This is a pretty minor issue, and maybe chamfering the PTFE would help here.

- Does this machine make sense?

- Of all the choices out there, Prusa is still a good one, and I appreciate what they’ve done for the 3d printing community over the years. While they are becoming more commercial focused and protective of their IP, they are rooted in RepRap and Open Source.

- I am glad they finally released an affordable Core XY, which seems to be where things are going. Bed Slingers, while simple and cheap, just aren’t as practical especially with the speeds we’re seeing on Core XY now days.

- If Prusa can deliver a better / more affordable MMU system, I think they will continue to be very relevant especially when considering Bambu and other Chinese manufacturers.

- I will continue to use my Voron 2.4, VzBot, and Voron 0’s which are all Open Source and have advantages over the Prusa. If I had to choose between a Prusa or one of these, I’d choose the Voron and VzBot.

- If I needed multicolor right now, I’d buy a cheaper Bambu, which I have (the A1 Mini). Between Bondtech’s new INDX and Prusa, I am hoping I can get rid of my Bambu soon. The Bambu machines just seem to be way more “consumer” focused and throw away appliances. I’d rather have something I can upgrade, like a Prusa or Open Source printer.

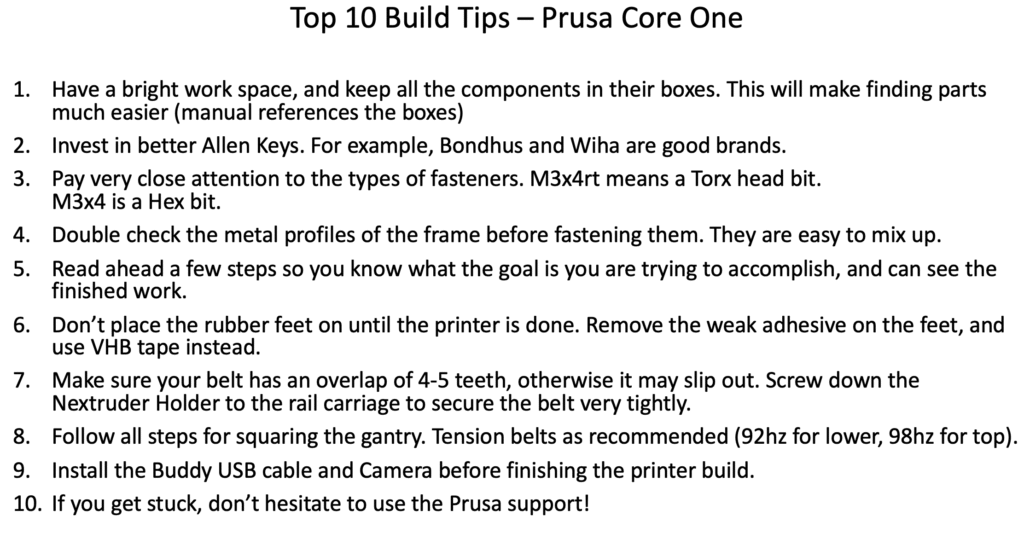

- My top 10 tips (as shown in video)

- So now what? What’s next?

- I am planning on printing a few projects on this printer, including an upcoming special project that I’m working with John on.

- I hope to see what the INDX may offer.

- I will be working on publishing my build videos. There is a ton of content to get through there!

As always, thanks for stopping by and reading my content. If you’d like to chat more, contact me on X/Twitter or leave a comment at my Youtube video that is linked above.